-

Products

-

Parts center

-

About UsFounded in 2008, WELLUN TECHNOLOGY has been adhering to the business philosophy of diligence, sincerity, trust and innovation, and is committed to introducing advanced woodworking machinery and equipment at home and abroad, and recommend it to domestic furniture enterprises.

-

NewsReal-time understanding of the company's current situation and furniture enterprises woodworking machinery equipment industry wind direction

-

Leave us a message

Get in touch with our team in time You help

*Note: Please be sure to fill in the information accurately and keep the communication open, we will contact you as soon as possible

Product advantage

Product application:Custom furniture, panel furniture, cabinets and closets, office furniture

◆ The drill pack is arranged in a compact and reasonable structure, and the cork holes and colloidal holes in any position of the plate can play two bits at the same time, which is better than the L-shaped conventional arrangement.

◆ The hole in the middle of the upper drilling bag is added with a dust suction device to solve the dust problem on the board surface.

◆ Vertical drilling with Tian-shaped combination drilling can drill adjacent large holes at the same time.

◆ The upper spindle is equipped with horizontal saw blade and vertical milling cutter at the same time. One motor can process two kinds of processes. The saw blade can process lamp groove and other side groove processes.

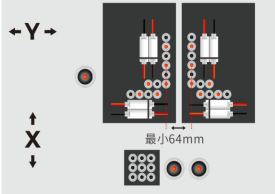

◆ Double drilling package vertical hole minimum simultaneous processing spacing 64mm, double drilling package left and right horizontal hole minimum plate width spacing 188mm.

◆ Double spindle design of the lower processing unit, customers can install 2 milling cutters of different processes according to needs (such as one can process straightener, the other can process lamp groove and other vertical slots), without manual knife change, improve processing efficiency.

◆ Minimum processing size 70mmX30mm.

◆ The feed clamp adopts a unique design, the middle hole, the small plate can be punched near the clamp position. Single clamp hand four positioning column processing small plate more stable.

◆ Booster pump only independent gas supply to the drilling package, for the use of the previous drilling package, the hole depth is more reliable and guaranteed.

◆ Intelligent positioning device, in the appearance of circular arc, fan plate positioning is not affected, rectangular plate is able to achieve the Angle error intelligent center function.

◆ After artificial annealing aging treatment, long-term stability.

◆ After large-scale gantry machining center overall precision machining, high precision.

◆ Adopt precision gear and rack drive, rack accuracy DIN6, after precision bed grinding. High precision, no special refueling maintenance.

◆ Adopt HaODE's own brand CNC drilling bag, using high-grade grinding gear transmission, high precision.

◆ Simultaneous drilling.

◆ Grooving at the same time.

◆ Double plate processing.

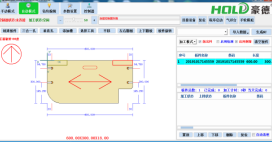

◆ Support CAD software drawing, import DXF file for processing.

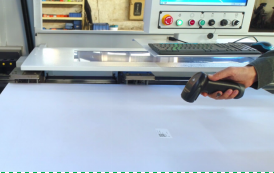

◆ Size automatic identification, docking software, display four side sealing side with thick book information, easy to place the board.

◆ Support simulation function, you can check the processing action in advance to avoid misprocessing.

◆ Big data analysis, statistics of the number of processing of each bit to reach the set number of use, prompting to change the bit.

◆ Processing statistics function: the two-dimensional code information of each piece of board is counted, the processing start time, the end time, the time spent, the upper and lower board time interval, which is convenient for staff performance management.

◆ The processing and the documents to be processed are displayed separately, which is convenient to check whether the processing plate is missing.

◆ Multi-axis CNC system, multi-channel technology, the machine in the processing of the workpiece pre-scan code to be processed a number of plates, queue up, reduce the time spent scanning code, at the same time discharge and processing control using multi-channel control technology, the board from the clamp, you can quickly return to the receiving point of the material processing.

◆ Network to achieve remote service, remote machine update, backup, bus communication technology, can more convenient to provide a variety of alarm information in detail, better docking MES system alarm interface.

Configuration description

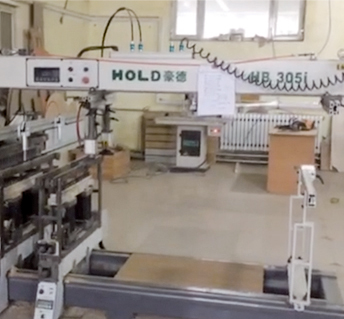

Product video

WELLUN TECHNOLOGY

Customer case

Customer site

Modern production base