【HOLD Machinery】 Make high order home manufacturing simpler and more high-end!【HOLD Machinery】 Make high order home manufacturing simpler and more high-end!

【HOLD Machinery】 Make high order home manufacturing simpler and more high-end!【HOLD Machinery】 Make high order home manufacturing simpler and more high-end!

On June 25, 2022, the sharing and exchange activity with the theme of "New exhibition hall, new scheme, best high-end product matching mode" was held at HOLD headquarters. The scene was full, industry leaders, factory owners, brand leaders, furniture designers representatives of more than 100 people participated in the activity.

As the co-organizer of the event, HOLD Machinery shared with you the CNC equipment such as the laser edge banding machine independently developed by HOLD Machinery, and visited the Guangdong production base of HOLD Machinery with the guests on site!

At the event, Liu Jingsheng, general manager of HOLD Machinery, shared around "Haode makes the production of high-end furniture simpler". Mr. Liu said that HOLD Machinery is deeply developed in the field of edge banding machines, of which the HOLD laser edge banding machine has been the first in China.

▲ Liu Jingsheng, general manager of HOLD Machinery

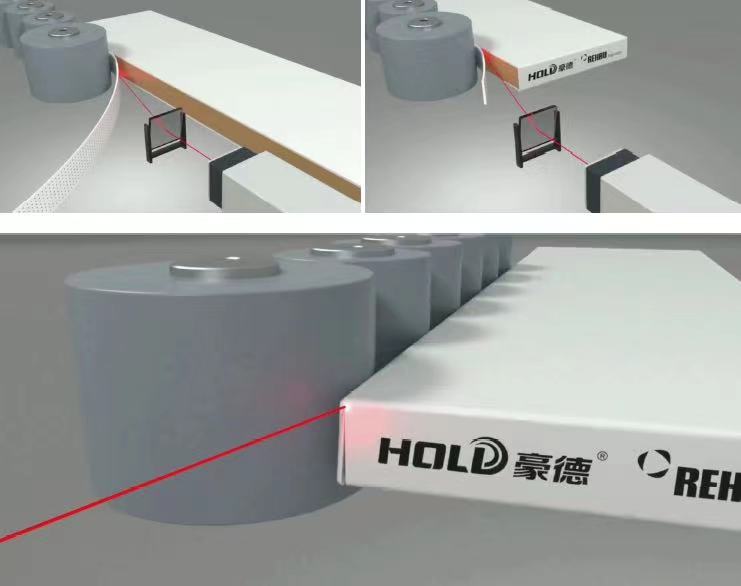

HOLD laser edge banding machine by HOLD Machinery lasted 3 years from 0 to research and development; At the source of research and development, adhering to the idea of integrated design, including laser, frame, guide rail, pressure beam, etc., almost every mechanism has carried out a new research and development, only to achieve higher quality seamless edge sealing; For the edge sealing of high-end custom laminated sheets, HOLD laser edge banding machine can achieve glue-free, rounded edge trimming with just one key switch.

HOLD laser edge sealing machine without glue, edge sealing after the surface clean and clean; Boot immediately, whether in the south or the north, are not affected by the temperature of the weather, no heating, very efficient.

▲HOLD laser edge banding machine schematic diagram

▲HOLD laser edge banding machine sample field experience

▲ Live audience mobile phone records

HOLD laser edge banding machine is not only the current high-end manufacturing used to create a seamless effect of the edge of the "necessity", but also in the economic environment brought about by the consumption upgrade of high-quality household products to create the demand, as well as the enterprise manufacturing upgrade brought about by the demand for advanced productivity. It is reported that a head supply chain brand has ordered a number of laser edge banding machines and about two production lines from HOLD Machinery, and will land in the near future.

▲HOLD laser edge sealing

After listening to Mr. Liu's share, the guests went to the HOLD Machinery workshop to visit and experience the HOLD laser edge banding machine, as well as other drilling and milling processing equipment, cutting equipment and so on.

▲ Workshop site

High order needs laser, China needs HOLD! In the future, HOLD will continue to develop more new products from the perspective of customers, apply more cutting-edge technology to woodworking machinery, and produce more stable, efficient and advanced equipment for customers.

Related information

- Wooden door intelligent production line, custom furniture production line, plate furniture unmanned production line, intelligent sorting line, packaging production line

- Dr. Shao Dialogue HOLD Jingsheng Liu | Master the core technology of laser edge banding machine, let the world see the spirit of Chinese woodworking equipment people

- Read all about [HOLD laser edge banding machine] 7 features!

- Property market untie, new consumption attack... High-end manufacturing requires advance layout, and you need [HOLD laser edge banding machine]

- 【HOLD Machinery】 Help Yongkang wooden door industry open a new chapter