![Read all about [HOLD laser edge banding machine] 7 features!](/uploadfiles/20230218/20230218142750_0204.png) Read all about [HOLD laser edge banding machine] 7 features!HOLD has the basis for making high-end edge banding machines, so is the HOLD laser edge banding machine just equipped with a laser device on the original high-end edge banding machine? The answer is no. HOLD laser edge banding machine from the source of r

Read all about [HOLD laser edge banding machine] 7 features!HOLD has the basis for making high-end edge banding machines, so is the HOLD laser edge banding machine just equipped with a laser device on the original high-end edge banding machine? The answer is no. HOLD laser edge banding machine from the source of r

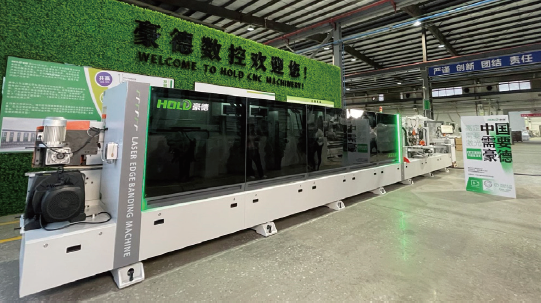

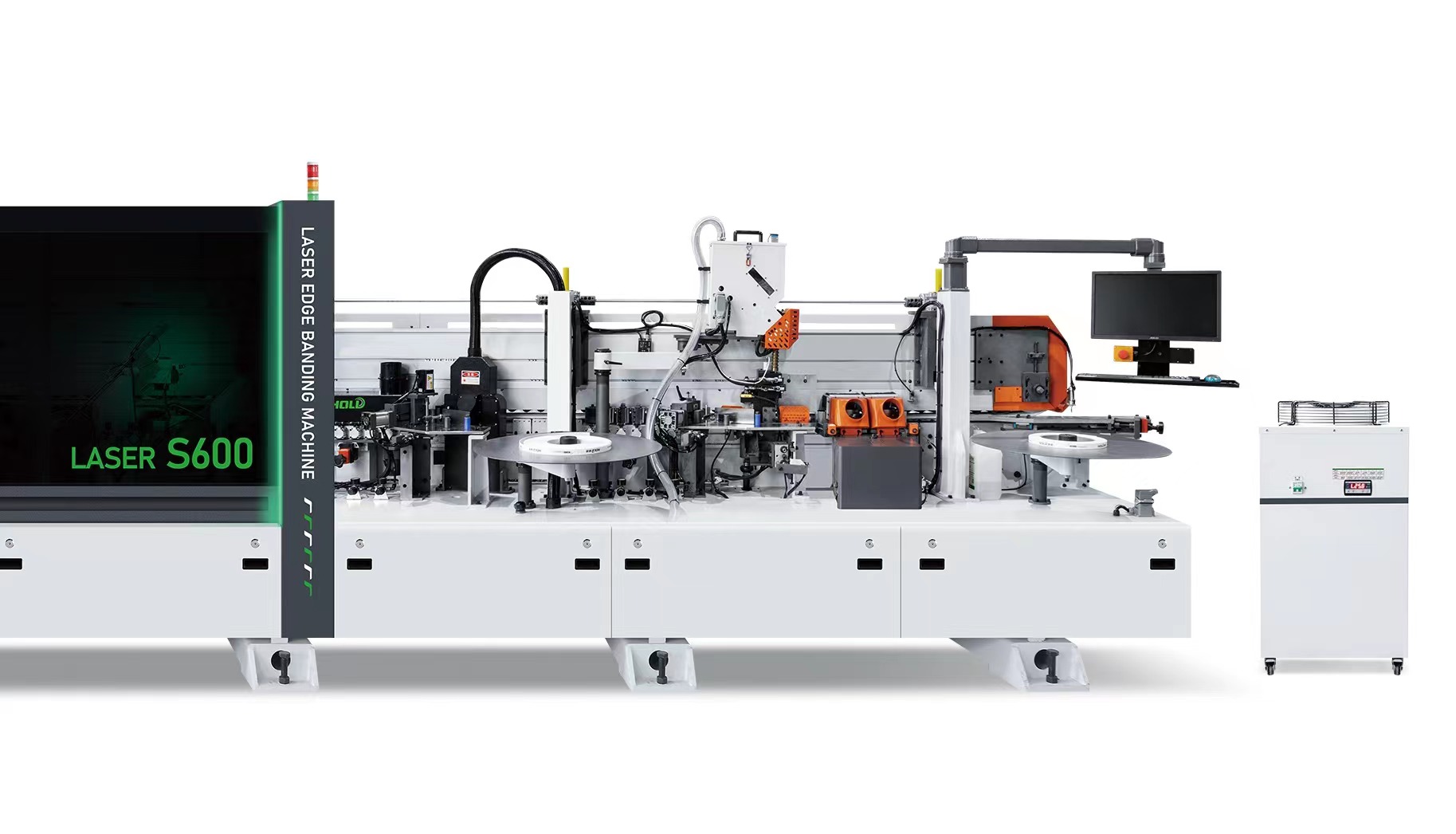

HOLD has the basis for making high-end edge banding machines, so is the HOLD laser edge banding machine just equipped with a laser device on the original high-end edge banding machine? The answer is no. HOLD laser edge banding machine from the source of research and development has been adhering to the idea of integrated design, each part has been a new design, only to achieve higher quality seamless edge sealing.

In order to adapt to the high-end and processing characteristics of the laser edge banding machine, HOLD laser edge banding machine starts from the source of research and development, including laser, frame, guide rail, pressure beam, etc., almost every mechanism has carried out a new research and development, thereby improving the stability of use; The entire laser system is also integrated with the system of the edge banding body, so it is not a simple "laser head + edge banding machine".

▲HOLD laser edge banding machine

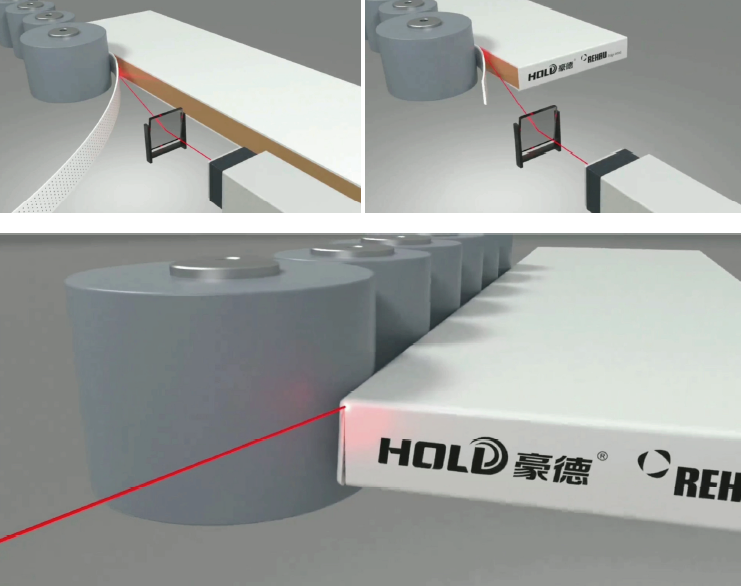

No glue is needed, the board is neat and clean, and the visual effect is perfect; Strong adhesive force, good waterproof performance, high and low temperature resistance; Boot immediately, no heating, environmental protection and pollution-free.

▲HOLD laser edge banding machine principle

The theoretical life of the laser generator is 100,000 hours.

▲HOLD laser edge banding machine laser head

The laser edge sealing does not need glue, and the laser excites the molecules of the functional layer and melts the functional layer material to penetrate the fiber structure to form a mechanical "riveting". And the use of laser edge sealing without preheating equipment, boot!

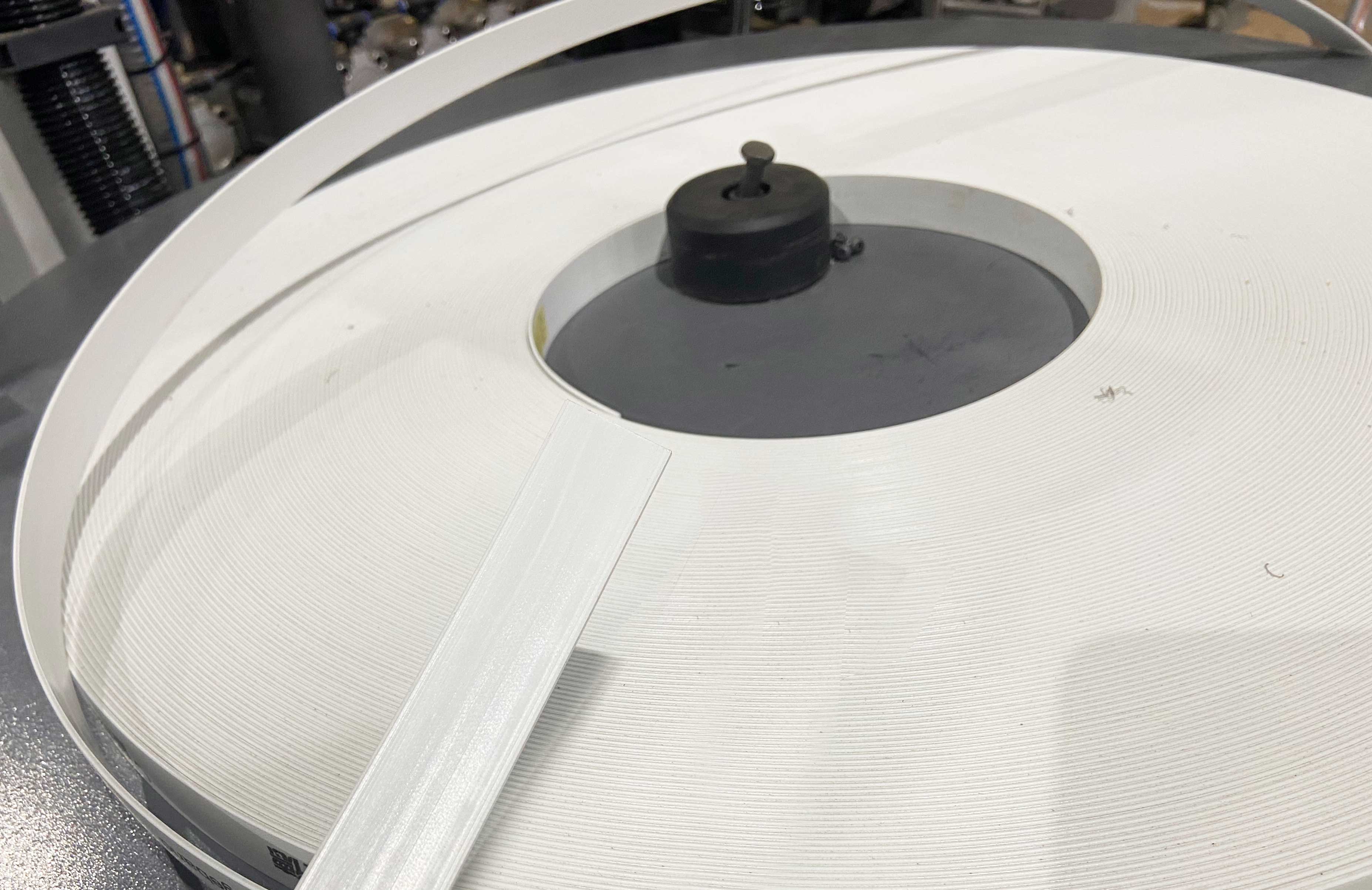

▲Edge banding tape produced by HOLD laser edge banding machine

For high-end custom edge sealing of common laminated sheets, HOLD laser edge banding machine has developed a special edge sealing mode, and easy to operate, no need to adjust the machine, just a point on the touch screen, you can achieve no glue line, trim round edge sealing.

▲HOLD laser edge banding system

▲Laser sideband

Taking into account the specific scenarios of real applications, the HOLD laser edge banding machine can not only seal the edge through laser, but also achieve the traditional adhesive edge sealing, and it is also the same high edge sealing quality. The HOLD laser edge banding machine is equipped with a single glue pot and double rubber nest, so it can be sealed with EVA or PUR, with high versatility, and a variety of different edge sealing needs can be solved on the same machine.

▲HOLD laser edge & glue seal

Including the common 1.2 ~ 1.5mm edge banding strip, as well as the 2.5 ~ 3mm office furniture edge banding strip, HOLD laser edge banding machine can be sealed, the thinest can be sealed 0.8mm edge strip; At the same time, it is also compatible with ABS, PP, acrylic and other edge sealing materials.

High order needs laser, China needs HOLD! In the future, HOLD will continue to develop more new products from the perspective of customers, apply more cutting-edge technology to woodworking machinery, and produce more stable, efficient and advanced equipment for customers

Related information

- Wooden door intelligent production line, custom furniture production line, plate furniture unmanned production line, intelligent sorting line, packaging production line

- 【 Doctor three talk 】 | HOLD hand in hand with Hualun machinery to create a new future of home manufacturing!

- Help home manufacturing cost reduction efficiency and quality double upgrade! 【HOLD Machinery】 Innovative technology opens 2023 for you!

- HOLD Machinery servo control, child door edge sealing machine

- HOLD Machinery 【 Wooden door equipment before maintenance 】