Dr. Shao Dialogue HOLD Jingsheng Liu | Master the core technology of laser edge banding machine, let the world see the spirit of Chinese woodworking equipment peopleMany furniture companies pay attention to edge banding machines and pay attention to higher quality edge banding; You can't unwrap a laser edge. Furniture companies do not necessarily need a laser edge banding machine? Why is HOLD's laser edge banding mac

Dr. Shao Dialogue HOLD Jingsheng Liu | Master the core technology of laser edge banding machine, let the world see the spirit of Chinese woodworking equipment peopleMany furniture companies pay attention to edge banding machines and pay attention to higher quality edge banding; You can't unwrap a laser edge. Furniture companies do not necessarily need a laser edge banding machine? Why is HOLD's laser edge banding mac

Many furniture companies pay attention to edge banding machines and pay attention to higher quality edge banding; You can't unwrap a laser edge. Furniture companies do not necessarily need a laser edge banding machine? Why is HOLD's laser edge banding machine worth your choice?

Not long ago, Liu Jingsheng, general manager of HOLD Machinery, and Dr. Shao, upstream and downstream of furniture, had an in-depth exchange around the HOLD laser edge banding machine.

▲Liu Jingsheng, general manager of HOLD

There are small bees in the upper and lower parts of the furniture. Liu, who saw HOLD for the first time, is in the live broadcast of the Chinese premiere of the HOLD laser edge banding machine - it is also the first live show of Liu.

In front of the camera, Mr. Liu was a little timid at the beginning, but when it came to the laser edge banding machine, Mr. Liu's eyes immediately had a luster, the experience of the research and development process, the characteristics of the HOLD laser edge banding machine, and so on. Little bee smile - Liu is a standard standard "science and technology man".

Indeed, Liu himself also said that he is not only a mechanical professional class, but also 30 years has not left the wood machine industry, one of the initial intentions of the research and development of laser edge sealing machine is to let "Chinese people master their own laser edge sealing technology" - such a pattern, such feelings, small bees can not help but respect Liu.

In addition, Liu and Dr. Shao also talked a lot; Mr. Liu's professional, dedicated, diligent and sincere spirit is very worthy of us, especially the majority of young friends...

▲HOLD General Manager Liu Jingsheng (right)

Furniture Upstream founder Dr. Shao (left)

As a home enterprise must buy laser edge banding machine? What are the characteristics and advantages of laser edge banding machine?

The first and most easily observed feature is that there is no glue, and the laser edge sealing machine can achieve true seamless edge sealing.

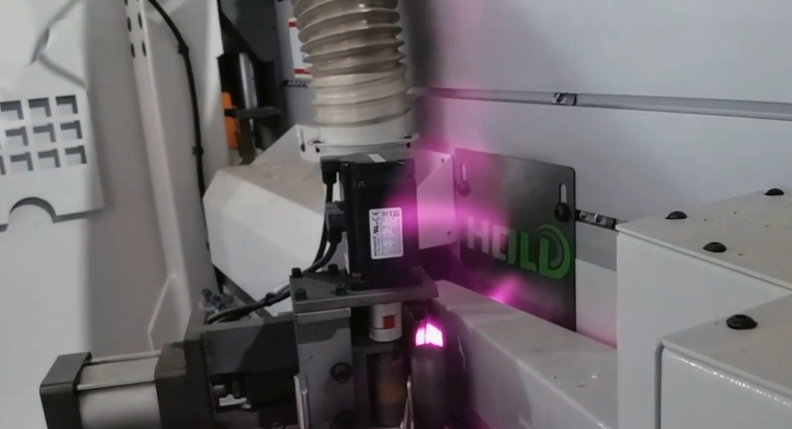

By laser melting this side band, the principle of laser edge sealing is to melt the functional layer of the side band by laser, because there is no "glue", so there is no "glue line". Secondly, the laser edge banding machine can be used on the boot, without preheating. And because there is no glue, the board does not need to be cleaned, and the comprehensive cost is low and the maintenance is simple.

Not only high definition, all want higher quality home, including office furniture, hotels, commercial space, etc., will need laser seal.

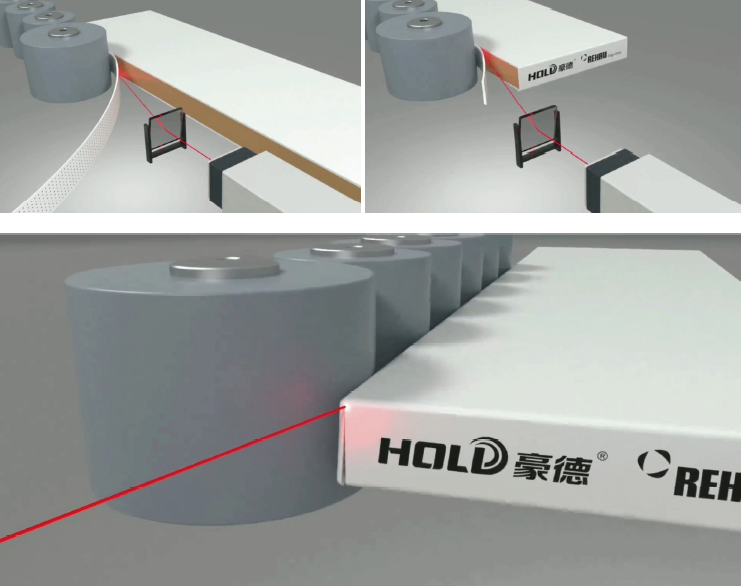

What is the principle of laser edge banding machine?

It can be understood so graphically that the laser in the laser edge banding machine emits a beam that will "melt" the functional layer behind the edge band base - of course, it does not actually belong to "melting". The "melted" functional layer is "welded" directly with the sheet, so the "welded" sheet is not sewn.

▲HOLD laser edge sealing principle

Why are laser edging machines so expensive? Why has it always been only imports? How hard is it to break through technologically?

The original laser edge sealing machine is expensive, on the one hand, it is only imported, the acquisition cost is high; On the other hand, the maintenance cost during use is high; Compared with domestic equipment, the maintenance response speed is also slow.

There are three difficulties in the domestic research and development of laser edge banding machine: first, the scarcity of relevant talents; Second, the lack of reference objects; Third, in China, laser edge sealing is a new area that needs to be explored.

Although we all know that laser edge banding machine is good, but for a long time only imported brands, domestic has not been done. But I understand that it is very important that if foreigners can do it, we Chinese must also be able to do it.

At the same time, according to my understanding of the laser application field, the current laser application technology in China has been relatively mature, and there are already dozens of listed laser companies. With the rise of high-end customization in China three years ago, I felt that the time had come. As the Chinese, we must master the core laser edge sealing technology, and we must produce the laser seal required by high-end enterprises.

For this reason, we specially recruited talents who understand laser application and formed a new team to develop this equipment together.

Did you ever think of giving up during the development process? What are the most impressive things about the development process?

At that time, there were some entanglements, but as a technical person, I still insist and have confidence - I firmly believe that China can do it! Foreigners can do it, the Chinese can do it, China must master the core technology of laser.

During the development process, our team sometimes stayed up all night discussing problems. Sometimes when I can't sleep at night, I suddenly think of a problem, feel good, should be able to solve it, and immediately get up to do research - so that one problem breaks through. The excitement and sense of accomplishment that comes from solving a problem is unforgettable. HOLD laser edge sealing machine because it is the first in China, is feeling the stones across the river, so technology developers can better understand the kind of pleasure to solve the problem.

The HOLD laser edge banding machine we use for customers today is a fully mature model, and we have iterated two versions internally before this, so you can completely rest assured that you can choose.

Why is the HOLD laser edge banding machine worth starting?

At first, we thought the problem was simple and we thought it would be done in 3 to 5 months, and then we found out that was not the case. The birth of the first generation of HOLD laser edge banding machine took 3 years and more than 10 million funds. There were a lot of difficulties in the first half year, there were some disputes in the process, and the team had some different opinions, but we finally stuck to it.

Although the first generation of HOLD laser edge banding machine was developed, we were not satisfied with it, and it was not finally put on the market, and then continued to research and development.

The development of the second-generation HOLD laser edge banding machine also took more than half a year. When the second generation was finally completed, it had reached 90% of our satisfaction, but it was still a little short of meeting our HOLD requirements, so we passed it again.

▲HOLD laser edge banding machine laser generator

Is this device an addition of laser components to our existing high-end edge banding machine, or an original development from the overall structure?

Laser seal is a high-end product, to "good horse with good saddle", so we have carried out a new design of the frame, guide rail, pressure beam, various institutions, etc., on the one hand, in order to match the extreme edge sealing effect of laser edge; At the same time, the sealing speed also requires the stability of the structure of the edge banding machine. Finally, high-end products should also have a worthy high-end appearance, so this is not simply increased laser components can be achieved.

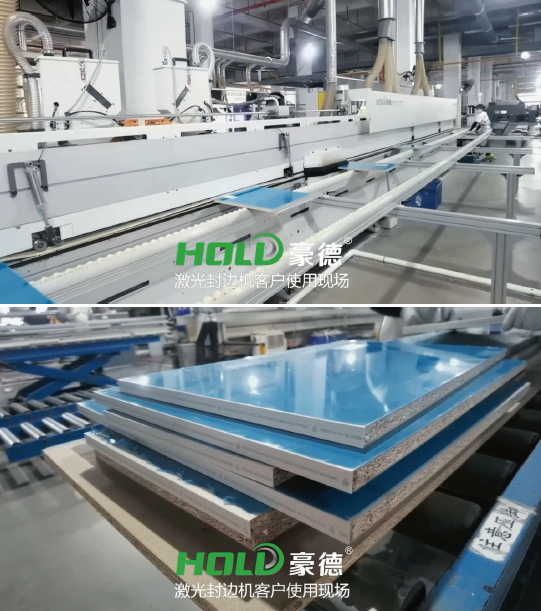

At present, the HOLD laser edge banding machine has been used in which region of the enterprise? How long did it take? How does it work? What about customer feedback?

The climate of the south is different from that of the north, adapted to this southern machine; Not necessarily in the north. In view of the differences in the use of laser edge banding machines in the northern and southern regions, we chose to use our laser edge banding machines in the north and the South at the same time during the study, and collected the corresponding data. At present, we have completed the improvement based on the collected data, and the Halder laser edge banding machine that is now on the market is a fully mature product.

Now the north and south have our HOLD laser edge sealing machine manufacturers. The intelligent laser device installed last year to complete the new software has performed very well in the whole process of use from the beginning to the present, and is highly recognized by customers.

▲HOLD light edge sealing machine customer use site

What is the continuous development direction of HOLD laser edge banding machine in the future?

Now the HOLD laser edge banding machine has been achieved to reduce the threshold of purchase. The future direction is to reduce the use and maintenance costs.

High-quality edge sealing is not only needed in the field of high definition, with the demand of consumers for higher quality of life, laser edge sealing machine should become a standard part of the edge - the best shape of the edge is, of course, can not see the glue line, while sticking very firm, which is the effect of laser edge sealing can be achieved. And in the future, we not only want to let more door panels, panels with laser sealing, we also want to let the cabinet, and even a wider range of home products are used in this high-quality edge sealing way, truly improve our quality of life.

▲HOLD laser edge banding machine is used on site

HOLD brand founded 18 years ago, standing in the perspective of business, what is your ideal?

The HOLD brand has been around for 18 years, but for me personally it's just a part of my industry career. I have never left woodworking machinery since 1989 when I was studying this mechanical major and came out to work. It has been nearly 30 years. The original intention is to do "good" products and do "good" enterprises, which are two basic points.

In the future, HOLD will always strive to solve the technical problems of edge banding. Such as invisible door sealing edge, wooden door groove sealing edge, child and mother door groove, narrow plate tracking chamfer, soft forming edge sealing. HOLD will continue to stand on the customer's point of view, develop more new products, and apply more cutting-edge technology to our woodworking machinery. HOLD wants to produce more stable, efficient and advanced equipment for our customers.

High order needs laser, China needs HOLD! It is believed that Haode will continue to stand in the perspective of customers, develop more new products, apply more cutting-edge technology to our woodworking machinery, and produce more stable, efficient and advanced equipment for customers.

Related information

- Wooden door intelligent production line, custom furniture production line, plate furniture unmanned production line, intelligent sorting line, packaging production line

- Read all about [HOLD laser edge banding machine] 7 features!

- Property market untie, new consumption attack... High-end manufacturing requires advance layout, and you need [HOLD laser edge banding machine]

- 【HOLD Machinery】 Help Yongkang wooden door industry open a new chapter

- 【HOLD Machinery】 Make high order home manufacturing simpler and more high-end!