HOLD Machinery 【 Wooden door equipment before maintenance 】The holiday is approaching, and the equipment will be shut down for a long time. In order not to affect the normal operation of the equipment after the holiday, we must take maintenance measures for the equipment. Therefore, HOLD Machinery gives the follo

HOLD Machinery 【 Wooden door equipment before maintenance 】The holiday is approaching, and the equipment will be shut down for a long time. In order not to affect the normal operation of the equipment after the holiday, we must take maintenance measures for the equipment. Therefore, HOLD Machinery gives the folloThe holiday is approaching, and the equipment will be shut down for a long time. In order not to affect the normal operation of the equipment after the holiday, we must take maintenance measures for the equipment. Therefore, HOLD Machinery gives the following suggestions on the maintenance measures of wooden door equipment:

Door opener

01

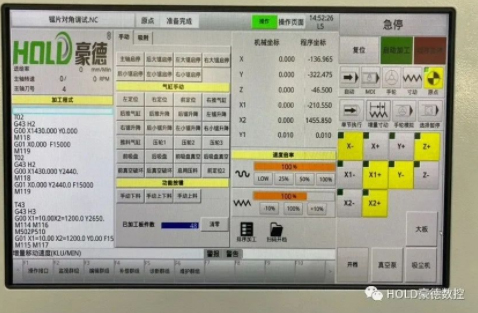

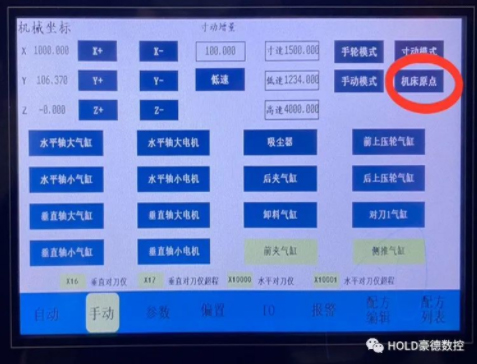

Return each axis to its original position.

02

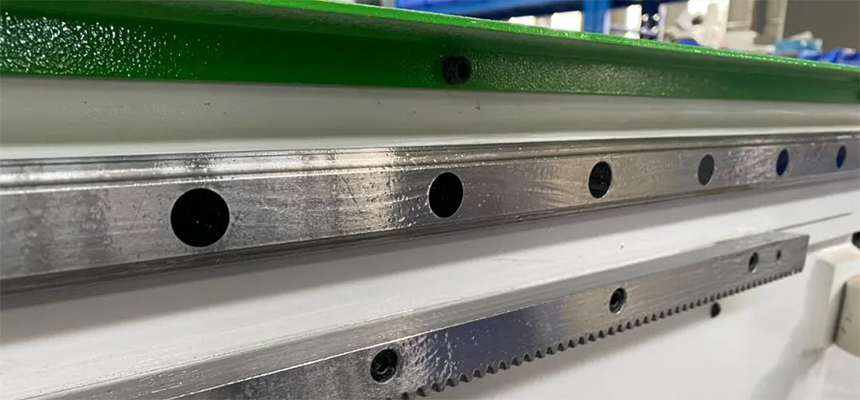

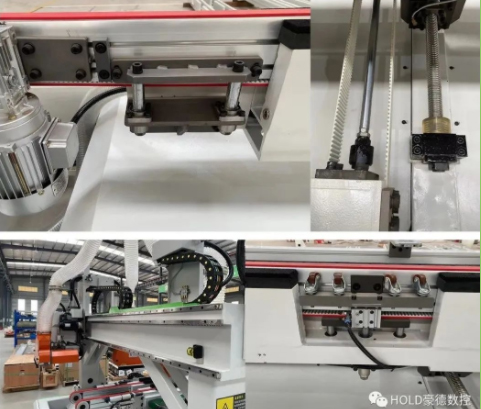

Rail rack maintenance: After cleaning the machine rail rack position, apply anti-rust oil or 68# rail oil to prevent rust.

03

Screw maintenance: screw and cylinder cleaning after rust treatment.

04

Saw blade maintenance: Open the cover of the saw blade in the case of power failure, clean the saw blade with a rag and apply a layer of anti-rust oil.

05

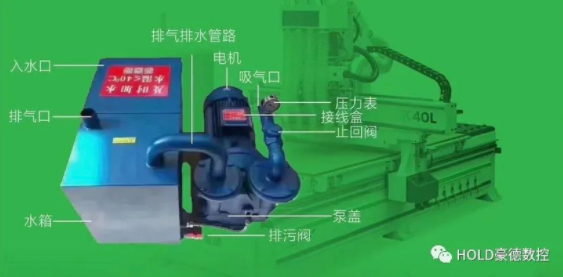

Vacuum pump maintenance: Open the drain valve to drain water, and clean the tank.

06

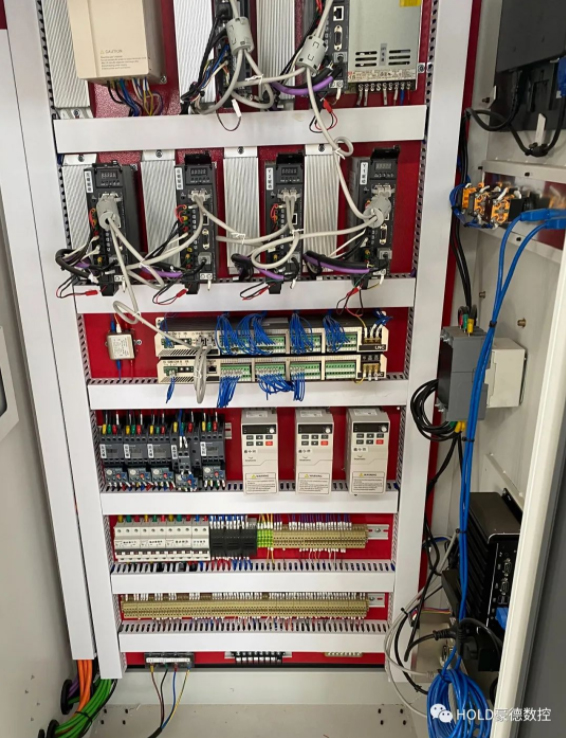

Electric box maintenance: First turn off the power, clean the dust in the distribution box with the air gun, close the electric box door, and put the mouse and keyboard into the electric box after cleaning. If the holiday time is long, it is recommended to put several packages of desiccant inside the electric box to prevent electrical components from moisture.

07

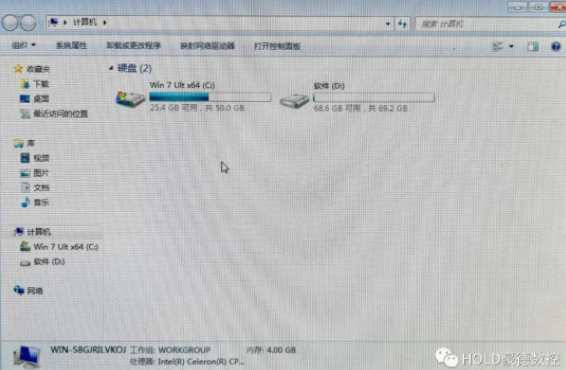

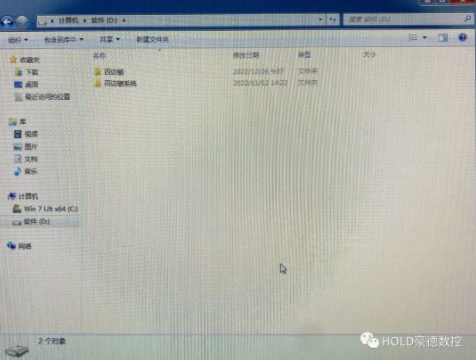

Software backup: Backup the processing files to the office computer to prevent data loss.

Wooden door four sides saw

01

Machine cleaning: Move the manual mode of the machine to the rear position, press the emergency stop switch and clean the dust and debris on the machine with the air pipe

02

Belt maintenance: Clean the dust and debris on the waste belt, lift the conveying cylinder, clean the wood chips in the conveying belt groove, ensure the smooth action of the feeding belt, clean the wood chips on the adsorption sponge, after cleaning can be covered with paper or sheet to prevent dust

03

Saw blade maintenance: In the case of power failure, loosen the handle of the saw cover, open the saw cover to clean the dust inside, use a rag to clean the dust on the surface of the saw blade, and apply oil to prevent rust.

04

Rail rack maintenance: Brush 68# rail oil or spray anti-rust oil on the whole machine transmission mechanism after cleaning to prevent rust

05

Motor maintenance: in the case of power failure, unscrew the fan port, regularly clean the wood chips and debris at the inlet, clean the dust and debris in the electric box and close the electric box.

06

Software backup: Copy the operating system and processing files on the computer to the U disk for archiving in the office computer to prevent data loss.

Wooden door lock hole machine

01

Return each axis to its original position.

02

Machine cleaning: in the state of power failure or emergency stop, use the air gun to clean the guide rail position and screw transmission position, open the back cover to clean the dust and debris in the machine.

03

Anti-rust of the whole machine: Apply 68# rail oil to the guide screw slider of the whole machine, or spray anti-rust oil.

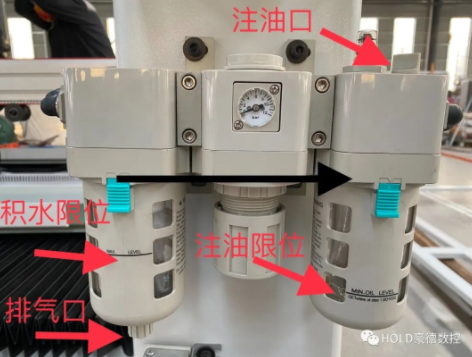

Triplet oil-water separator (applicable to all models) : check both sides of the limit in the gas off state, unscrew the exhaust port to drain water, check the triplet oil injection limit, unscrew the oil injection port to regularly fill 32# hydraulic oil or 68# rail oil.

Oil pump maintenance (applicable to all models) : Check the amount of oil in the oil pot every week and whether there is oil to the transmission part to keep the machine working with oil.

Related information

- Wooden door intelligent production line, custom furniture production line, plate furniture unmanned production line, intelligent sorting line, packaging production line

- Read all about [HOLD laser edge banding machine] 7 features!

- 【 Doctor three talk 】 | HOLD hand in hand with Hualun machinery to create a new future of home manufacturing!

- Help home manufacturing cost reduction efficiency and quality double upgrade! 【HOLD Machinery】 Innovative technology opens 2023 for you!

- HOLD Machinery servo control, child door edge sealing machine