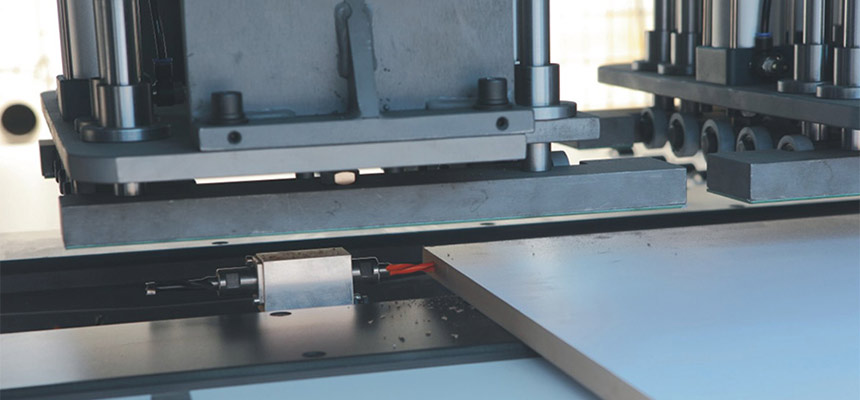

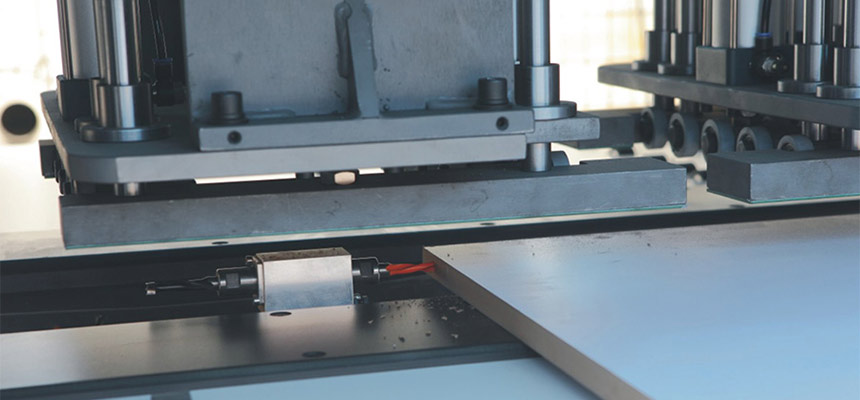

Requirements of position detection device for CNC drilling machine in DongguanThe function of the position detection device is to detect the displacement and speed of the moving parts of the automatic drilling machine, and send a feedback signal to form a closed-loop control system, and convert it into a digital signal and send it

Requirements of position detection device for CNC drilling machine in DongguanThe function of the position detection device is to detect the displacement and speed of the moving parts of the automatic drilling machine, and send a feedback signal to form a closed-loop control system, and convert it into a digital signal and send it The role of the position detection device is to detect the displacement and speed of the moving parts of the automatic drilling machine, and send feedback signals to form a closed-loop control system, and convert it into a digital signal and send it back to the CNC device for comparison with the pulse command signal to control the correct operation of the drive components. The precision and resolution of the numerical control system depend on the accuracy of the position detection device. Different types of CNC machine tools have different precision requirements for position detection components, detection systems and the highest moving speed of measured parts.

At present, the highest level of detection components and systems is: when the highest moving speed of the measured part is 240m/min, the resolution of the detected displacement (the smallest displacement that can be detected) can reach 1m, such as 0.1m when 24m/min. The highest resolution can reach 0.01pm. The CNC drilling machine has the following requirements for the position detection device.

1, reliable work, strong anti-interference because the machine has a motor, solenoid valve and other electromagnetic induction components and the presence of lubricating oil and cutting fluid in the cutting process, therefore, the position detection device is required to have a strong anti-interference ability to electromagnetic induction, but also requires the device is not afraid of oil and water pollution. In addition, due to the generation of heat during the cutting process, the position detection device is also required to have a strong adaptability to the ambient temperature.

2, meet the requirements of accuracy and speed

Under the condition of meeting the maximum displacement speed of CNC drilling machine, the position detection device is required to achieve certain detection accuracy and small cumulative error. With the development of CNC drilling machine, its precision and speed are getting higher and higher, so the position detection device must meet the requirements of high precision and high speed of CNC drilling machine.

3, easy to install and maintain

When installing the position detection device, it must have certain installation accuracy requirements, and its installation form and position must also be convenient for empty maintenance.

4, low cost, long life

Due to the impact of the use of the environment, the position detection device also requires good dust, oil mist, chip and other characteristics.

CNC drilling machine features:

1, fast speed, high precision, tap out of the teeth can be detected by the dental gauge. Can be used for high-speed continuous cycle operation, special motor can be durable, can achieve automation, pitch automatic tapping machine multi-axis drill can operate multiple equipment at the same time, can significantly save labor costs!

2, working principle: positive -- reverse -- positive -- reverse hh multi-axis drill continuous cycle and positive -- reverse -- stop one-way cycle has a specific multi-axis drill key switch to operate

Can also be installed foot switch, selective operation, continuous, one-way, cycle can be automatic. The operator's hands can completely leave the machine to achieve automatic work, and beginners can also operate smoothly.

3, high precision tapping stroke adjustment is simple, automatic reverse device can freely adjust the tapping stroke, multi-drilling, automatic drilling machine, shallow holes and holes of low processing workpiece can also be easily adjusted, double safety device can prevent the damage of the screw tap, spindle rotation and up and down, advance and retreat knife special double safety clutch, multi-axis drilling movement, spindle can automatically stop, reverse cutting tool will also damage the tool .

4, tooth pitch A, B gear with A, B spindle and the main shaft according to the tooth pitch to complete coordination, vertical stability, precision, precision is particularly high, screw tapping teeth forward and backward perforated drill will be able to run freely. And at the same time, depending on the excellent processing items, the porous drill will cause different thickness threads, for thin sheets and light metal, synthetic resin and other soft products can also tap perfect threads. The square type adjustable spindle structure is the same as the round type.

Related information

- Wooden door intelligent production line, custom furniture production line, plate furniture unmanned production line, intelligent sorting line, packaging production line

- Dr. Shao Dialogue HOLD Jingsheng Liu | Master the core technology of laser edge banding machine, let the world see the spirit of Chinese woodworking equipment people

- Read all about [HOLD laser edge banding machine] 7 features!

- Property market untie, new consumption attack... High-end manufacturing requires advance layout, and you need [HOLD laser edge banding machine]

- 【HOLD Machinery】 Help Yongkang wooden door industry open a new chapter