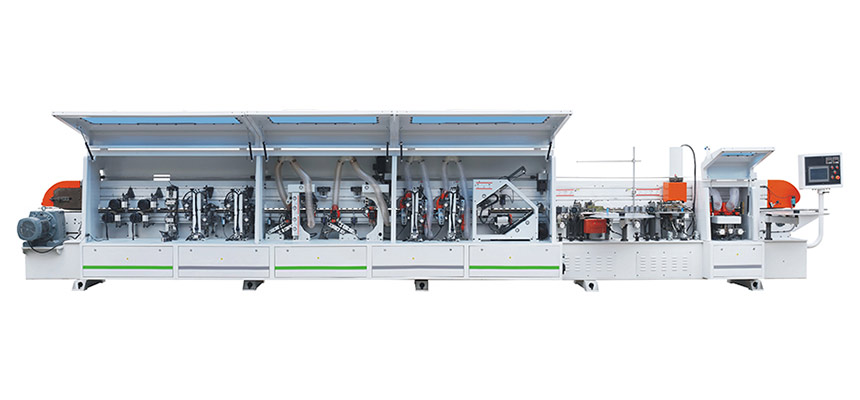

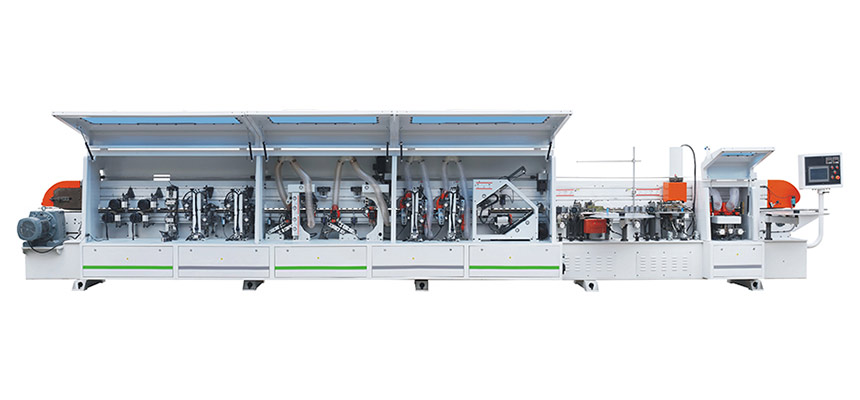

Dongguan automatic edge sealing machine maintenance tipsFirst of all, the production material of the automatic edge banding machine itself is metal, and the object of its operation is also metal. The working principle is to use the friction and impact between the metals to achieve the purpose of cleaning and o

Dongguan automatic edge sealing machine maintenance tipsFirst of all, the production material of the automatic edge banding machine itself is metal, and the object of its operation is also metal. The working principle is to use the friction and impact between the metals to achieve the purpose of cleaning and oFirst of all, the production material of the automatic edge banding machine itself is metal, and the object of its operation is also metal. The working principle is to use the friction and impact between the metals to achieve the purpose of cleaning and optimization, so the wear in the working process of the edge banding machine is inevitable and the wear situation will be more serious. Then the biggest point for the maintenance problem is the use of polishing oil, the purpose of adding lubricating oil is to slow down the degree of wear of the machine, extend its scrap time, but the lubricating oil can not be overused and the effect of improving wear is not particularly obvious. Therefore, the key is to maintain the accessories of the edge sealing machine, the machine should be checked regularly, and the damaged components should be replaced in time, especially the damaged steel balls should be replaced in time, otherwise it will lead to the damaged steel balls wearing castings.

Automatic edge banding machine equipment installation steps:

1. Remove the packaging of fixed mechanical parts.

2. Place the machine on the ground and adjust the level.

3. The roll sealing material is fixed on the machine with the storage turntable.

4, Connect the external power cable, 220V50HZ three-phase four-wire power supply, the total power cable diameter should be more than 4 square centimeters.

5. Connect the air source.

6. Connect the suction pipe to the dust removal equipment.

7, check whether the voltage is normal, to ensure that the compressed air is enough and dry.

Related information

- Wooden door intelligent production line, custom furniture production line, plate furniture unmanned production line, intelligent sorting line, packaging production line

- Dr. Shao Dialogue HOLD Jingsheng Liu | Master the core technology of laser edge banding machine, let the world see the spirit of Chinese woodworking equipment people

- Read all about [HOLD laser edge banding machine] 7 features!

- Property market untie, new consumption attack... High-end manufacturing requires advance layout, and you need [HOLD laser edge banding machine]

- 【HOLD Machinery】 Help Yongkang wooden door industry open a new chapter