Dongguan CNC cutting board saw operation of the four major preparation and boot preparationFirst of all, clean up the machine and the working place; Secondly, check whether the suction system is normal; Then check whether the saw blade is sharp; Whether the size saw blade is in a straight line; Test the machine for about one minute to see if th

Dongguan CNC cutting board saw operation of the four major preparation and boot preparationFirst of all, clean up the machine and the working place; Secondly, check whether the suction system is normal; Then check whether the saw blade is sharp; Whether the size saw blade is in a straight line; Test the machine for about one minute to see if th

Nc cutting board saw start-up preparation

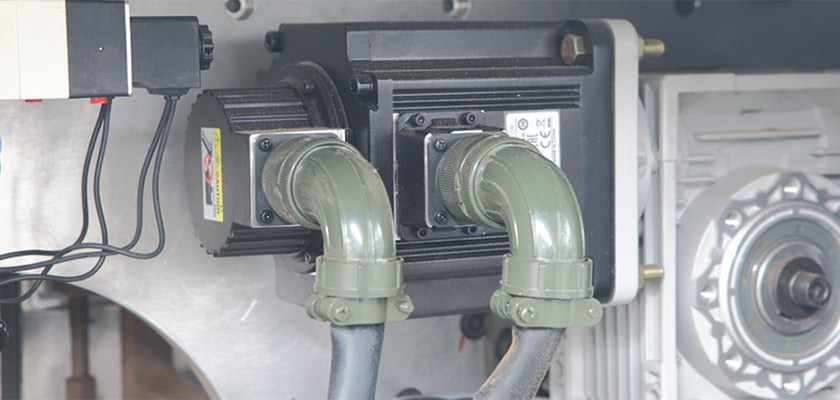

1. Check whether the power switch of the CNC cutting saw is pushed in place, and whether the current has a lack of phase, so as not to burn the machine motor due to lack of phase when the machine is activated.

2, clean the machine table and work place. When operating a CNC cutting board saw, the person standing at the boot must keep the legs straight, the body straight, can not lie, and lean on the operating platform.

3. Check whether the CNC cutting saw blade is vertical with the sliding table, and whether the size saw blade is in the same straight line. Test the machine for about one minute to see whether the CNC cutting saw runs normally.

4. First push the push bed several times to check whether the slide is smooth, and keep the slide clean and smooth.

5. Prepare materials and accessories.

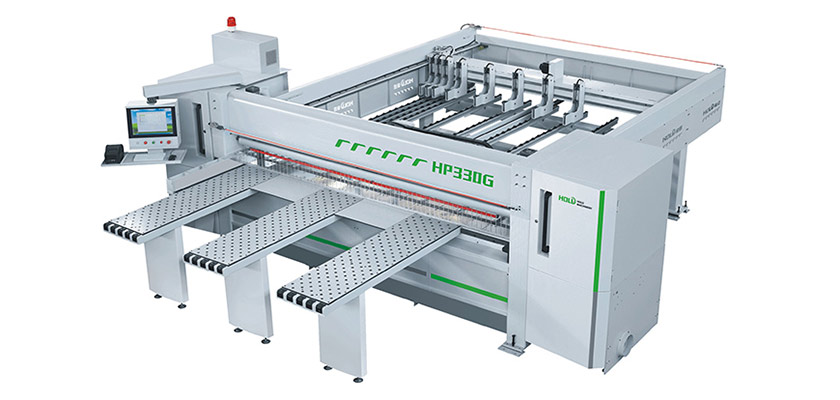

CNC cutting saw has the characteristics of simple operation, stability, safety and high efficiency, and is the necessary equipment for furniture mass, standardization, mechanization and professional production. CNC board saws produced abroad and in Shenyang have more adaptability and stability, and their accuracy meets the requirements of solid wood and composite board cutting.

Related information

- Wooden door intelligent production line, custom furniture production line, plate furniture unmanned production line, intelligent sorting line, packaging production line

- Read all about [HOLD laser edge banding machine] 7 features!

- 【 Doctor three talk 】 | HOLD hand in hand with Hualun machinery to create a new future of home manufacturing!

- Help home manufacturing cost reduction efficiency and quality double upgrade! 【HOLD Machinery】 Innovative technology opens 2023 for you!

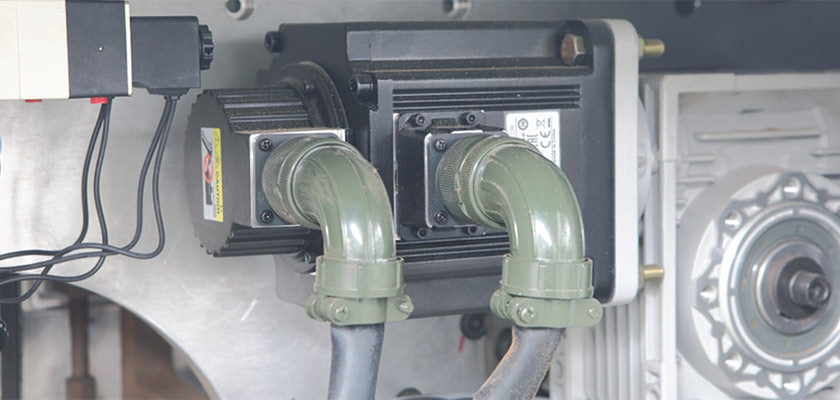

- HOLD Machinery servo control, child door edge sealing machine