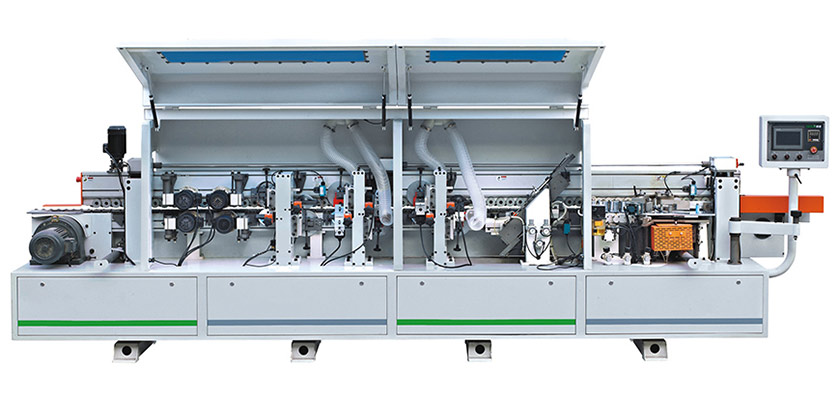

Dongguan automatic edge sealing machine installation stepsBefore installation, check whether the ground is strong and flat, it is best to install the machine on the concrete surface to ensure the stability of the machine after adjustment, and require the installation site light is not less than 500LUX, and ensur

Dongguan automatic edge sealing machine installation stepsBefore installation, check whether the ground is strong and flat, it is best to install the machine on the concrete surface to ensure the stability of the machine after adjustment, and require the installation site light is not less than 500LUX, and ensurBefore installation, check whether the ground is strong and flat, it is best to install the machine on the concrete ground surface to ensure the stability of the machine after adjustment, while requiring the installation site light is not less than 500LUX, and ensure that there is sufficient space for installation, operation work access, repair and maintenance.

The automatic edge banding machine can redecorate the uneven plate or the ripple, burr or non-vertical phenomenon caused by the cutting saw and cutting saw processing, so that the plate sealing boundary surface is smooth, so that the edge strip and the plate are closely bonded, so as to achieve a better edge sealing effect.

The machine installation steps are as follows:

1. Remove the packaging of fixed mechanical parts.

2. Place the machine on the ground and adjust the level.

3. The roll sealing material is fixed on the machine with the storage turntable.

4, Connect the external power line, 220V 50HZ three-phase four-wire power supply, the total power line diameter should be more than 4 square centimeters.

5. Connect the air source.

6. Connect the suction pipe to the dust removal equipment.

7, check whether the voltage is normal, to ensure that the compressed air is sufficient and dry.

The automatic edge banding machine can redecorate the uneven plate or the ripple, burr or non-vertical phenomenon caused by the cutting saw and cutting saw processing, so that the plate sealing boundary surface is smooth, so that the edge strip and the plate are closely bonded, so as to achieve a better edge sealing effect.

Related information

- Wooden door intelligent production line, custom furniture production line, plate furniture unmanned production line, intelligent sorting line, packaging production line

- Read all about [HOLD laser edge banding machine] 7 features!

- 【 Doctor three talk 】 | HOLD hand in hand with Hualun machinery to create a new future of home manufacturing!

- Help home manufacturing cost reduction efficiency and quality double upgrade! 【HOLD Machinery】 Innovative technology opens 2023 for you!

- HOLD Machinery servo control, child door edge sealing machine