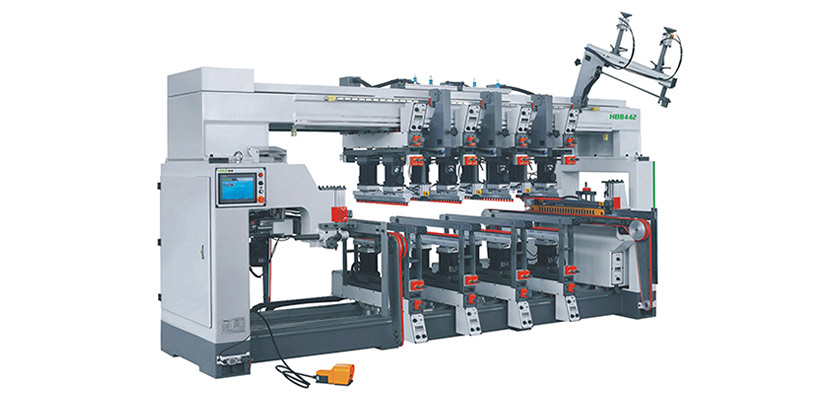

Dongguan row drill manufacturers brief analysis of the correct use of woodworking row drillWith the width of the drawer on both sides of the plate as the size benchmark, left and right custom sub-; The two thick skins of the side panels are together and placed in the middle position, and the left and right sides of the drawer panel are increase

Dongguan row drill manufacturers brief analysis of the correct use of woodworking row drillWith the width of the drawer on both sides of the plate as the size benchmark, left and right custom sub-; The two thick skins of the side panels are together and placed in the middle position, and the left and right sides of the drawer panel are increase1, the plate is classified according to the size of the specification, the panel, side panel, etc. must be selected before drilling, and the plate must be handled lightly

2. Customize the sheet size with the largest number of widths;

3, first use the flat drill and vertical drill to finish all the large flat buckle, the same system after finishing the hole, if you need to move the system, after adjusting the hole position operation as above;

4, the width of the drawer on both sides of the plate as the size of the benchmark, left and right custom sub-; The two thick skins of the side panels are matched together and placed in the middle position, and the left and right sides of the drawer panel are increased by 10mm and then placed on the platform.

5. After finishing the hole, put all the plates on the trolley, do not fall, and then put them together according to the size of the plates;

6, turn off the drill power supply, blow the saw foam on the machine clean;

7, each time to mobilize the system or change the drill bit or switch the drilling position button, the machine should be self-checked, when the machine abnormal situation, should immediately press the emergency stop button, timely shutdown.

Matters that should be noted in the use of woodworking row drill manufacturers:

When using woodworking row drilling, we need to pay attention to many problems, among which the correct use is important, and our use of woodworking row drilling is also related to safety issues, so our row drilling must be careful about the use of drill bits. And we also have to reasonably protect the drill bit, because the drill bit is very important for drilling. When using woodworking bank drill, pay attention to prevent vibration collision. If the drilling vibration is too violent, it has a great impact on the control of the drilling machining precision. It is easy to produce substandard waste products. Therefore, we usually use to keep every part of the drill well, and we avoid damaging the parts to produce some unnecessary machine damage. When using woodworking row drill for parts processing, we should carry out microscope processing for some parts with very high precision requirements, so that the error of woodworking row drill can be greatly reduced. Our woodworking drill requires a certain degree of positioning accuracy during installation. And in this case, our precision adjustment should be adjusted and required according to their own product needs.

Row drill manufacturers woodworking row drill the correct use

1. Please read the instructions carefully before operating this machine. Check whether the ground cable is firmly grounded and the components work properly. The operating position is well lit (do not operate the machine without training).

2, operation to do three tight, three no, one attention. Three tight: tight clothes, tight waist, tight sleeves; No: no tie, no hand jewelry, no gloves; First caution: Pay attention to eye protection.

3, before starting the machine, please pay attention to all warning signs.

4. Find out the rotation direction of the drill and select the drill correctly.

5. Do not approach or touch moving or rotating parts.

6, if the horizontal drilling and vertical drilling interference, must choose asynchronous work.

7. Do not adjust or maintain the machine before the main power supply is turned off.

Related information

- Wooden door intelligent production line, custom furniture production line, plate furniture unmanned production line, intelligent sorting line, packaging production line

- Read all about [HOLD laser edge banding machine] 7 features!

- 【 Doctor three talk 】 | HOLD hand in hand with Hualun machinery to create a new future of home manufacturing!

- Help home manufacturing cost reduction efficiency and quality double upgrade! 【HOLD Machinery】 Innovative technology opens 2023 for you!

- HOLD Machinery servo control, child door edge sealing machine