HOLD Machinery 【 Edge banding machine before maintenance 】The holiday is approaching, and the equipment will be shut down for a long time. In order not to affect the normal operation of the equipment after the holiday, we must take maintenance measures for the equipment. Therefore, HOLD Machinery gives the follo

HOLD Machinery 【 Edge banding machine before maintenance 】The holiday is approaching, and the equipment will be shut down for a long time. In order not to affect the normal operation of the equipment after the holiday, we must take maintenance measures for the equipment. Therefore, HOLD Machinery gives the folloThe holiday is approaching, and the equipment will be shut down for a long time. In order not to affect the normal operation of the equipment after the holiday, we must take maintenance measures for the equipment. Therefore, HOLD Machinery gives the following suggestions on the maintenance measures of the edge banding machine:

01

Equipment surface: Clean the surface of the equipment with an air gun and a rag every day, and wipe it with your hands after cleaning. There should be no dust on your hands, and various items should not be placed on the surface at will.

02

Display screen: Clean the surface of the equipment with an air gun and a rag every day. The interface displays normally. Wipe with your hands after cleaning.

03

Polishing cloth wheel: Check the polishing cloth wheel regularly and replace it in time if there is any problem.

04

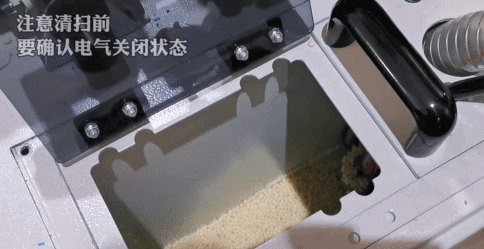

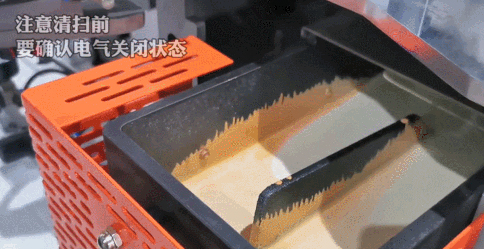

Plastic box: clean the plastic box with air gun and rag every day before starting, check whether there is foreign matter in the plastic box and clean it in time, check the plastic box or glue at irregular intervals during operation, pay attention to not falling glue; After adding colloidal particles, cover the rubber box and lock it tightly.

Ordinary sol: Turn on but do not work for a long time, please close the heating button to prevent the glue does not flow and produce paste.

Fast sol: Clean the remaining glue in the rubber box every day, and clean it at the working temperature of the power supply.

05

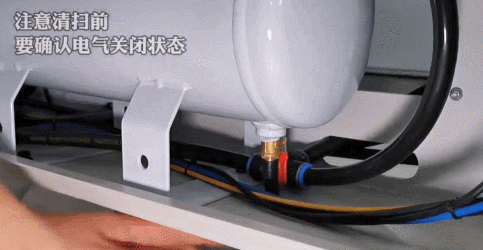

Gas storage tank: Drain the gas storage tank once a week. First, find the red switch below to open the switch, and the water will flow out through the black hose.

06

Vacuuming pipe: Clean the surface with air gun and rag every day to keep it clean, pay attention to the suction of the pipe in time when working.

07

Head guide rail: check and clean the dust of the head guide rail before starting every day, and check whether the lubricator needs to add lubricating oil every day.

08

Motor: Clean the appearance with an air gun and a rag every day to keep it clean, the motor should not have abnormal noise, and the motor temperature should not be too high (hot).

09

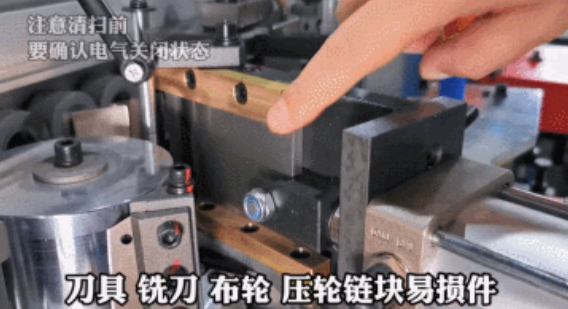

Cutting tool: cutting tool, milling cutter, cloth wheel, press wheel chain block wearing parts;

Saw blade - clean with air gun every day, check the wear of each wearing part before starting and replace it in time;

Scraper, tracking knife, trimming knife -- each shift to check whether there is silk winding of each motor spindle timely cleaning, abnormal treatment in time;

Press wheel press block - manual oil is carried out once a day through the hand pump, and the lubricating oil is transferred to the chain through the brush.

10

Triplet: clean with air gun and rag before starting, drain water to air filter once before starting, water and exceed the specified position can not have impurities inside, check the oil gauge before starting, less than 1/3 need to add anti-wear hydraulic oil to 2/3. When adjusting the amount of oil, turn counterclockwise to add a large amount, and reduce the amount of oil clockwise.

11

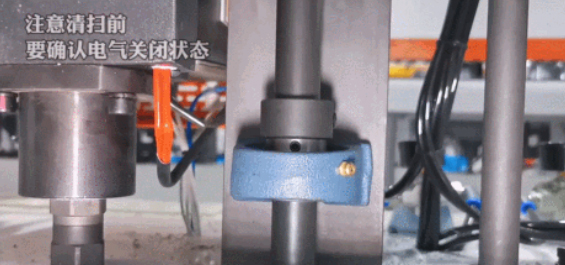

Universal coupling: once a week, clean and check the rust of the pressed and coated universal coupling sleeve, and clean and check the rust of the universal coupling sleeve, and inject oil or anti-rust oil into the joint of the universal coupling.

12

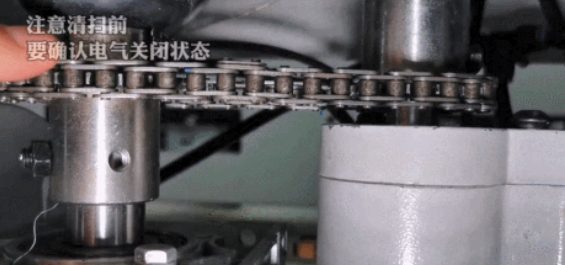

Gear box: Clean the gear box with an air gun before work, pay attention to whether there is abnormal noise when the gear box is working, and apply butter to the chain by hand.

13

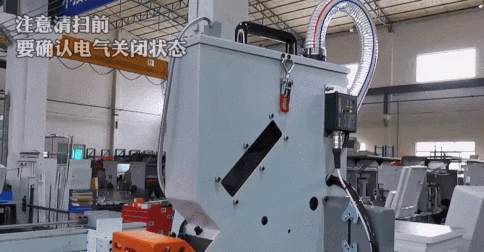

External maintenance of the whole machine: After cleaning and maintaining the whole machine, it is recommended to cover the whole machine with pearl cotton and stretch film.

Related information

- Wooden door intelligent production line, custom furniture production line, plate furniture unmanned production line, intelligent sorting line, packaging production line

- Read all about [HOLD laser edge banding machine] 7 features!

- 【 Doctor three talk 】 | HOLD hand in hand with Hualun machinery to create a new future of home manufacturing!

- Help home manufacturing cost reduction efficiency and quality double upgrade! 【HOLD Machinery】 Innovative technology opens 2023 for you!

- HOLD Machinery servo control, child door edge sealing machine